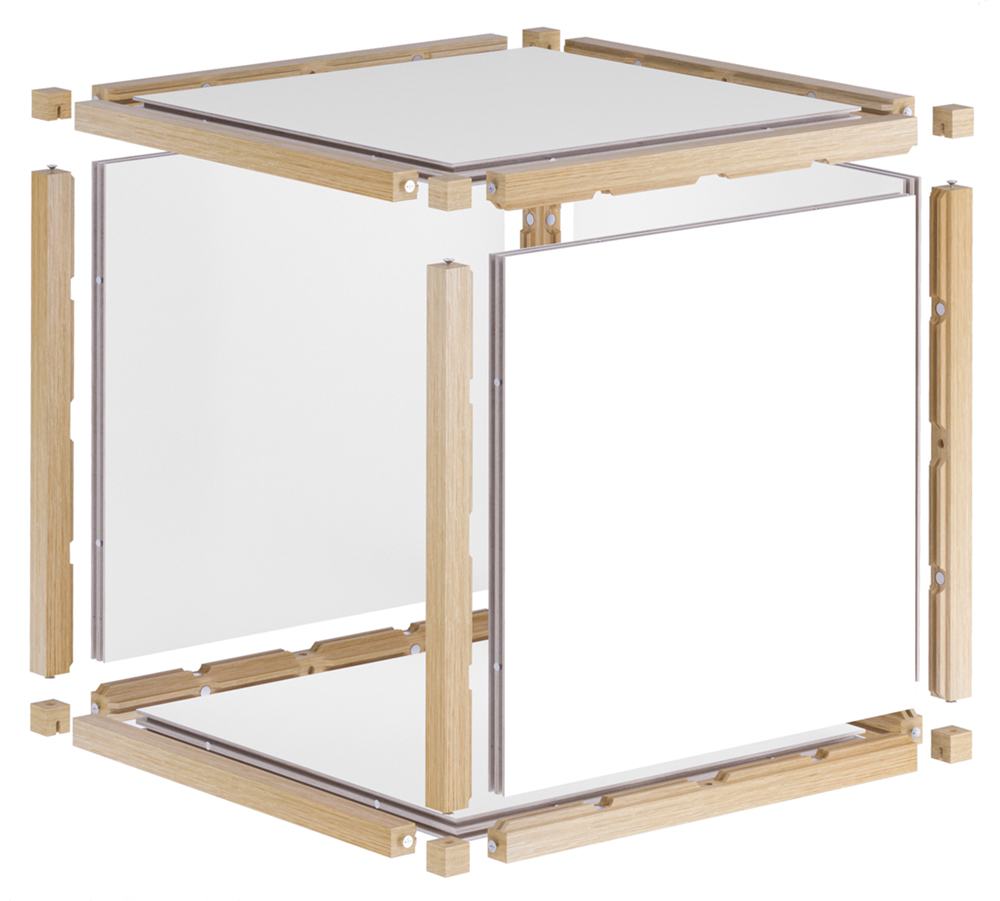

The TAVAR furniture system consists of components that are assembled by a newly developed double-groove and tongue / magnet system.

Taking the static requirements into consideration, the system can be built in a 20 cm grid in all three axial directions.

Boards and connectors are made of wood and are manufactured in local craft workshops.

1. Boards:

The boards have circumferential double grooves. On all edges wooden connectors are attached with the appropriate grooves, which are held by magnetic force.

There are the following lengths and widths: 18 / 38 / 58 / 78 / 98 / 118 / up to 198 cm.

2 smaller boards + 1 connector give the size of the next board.

2. Connectors:

The connectors have double tongues which are attached to all edges of the boards to the matching double grooves and hold by magnetic force.

Thus, the boards are completely framed by the connectors. The connectors finish the boards smoothly or form the connection to the next closing board.

3. Cubes:

Wherever the ends of two or more connectors meet – whether over corner or straight – a gap is left.

This is always filled with a wooden cube. Its installation prevents the furniture from being torn apart in case someone pulls tightly on one side.

Assembly

The furniture is assembled layer by layer from bottom to top. The furniture disassembly takes place in reverse order. Board and connector tighten during assembly.

Please be so careful that you do not pinch the skin of your fingers when joining board and connector. Wearing gloves prevents this.

The special trick with the TAVAR system: The magnets are each wider than the grooves or tongues in which they are attached.

Therefore, board and connector can not be moved to each other, but can only be merged at the same height of the magnet pairs.

Inserting the boards:

When you have provided your horizontal base board with connectors, you can carefully add the first vertical wall.

Once you build a three dimensional corner with a vertical connector and another board, you have stability.

The boards are being used in all directions, as bottom, side or rear wall.

If a magnet should come loose:

The magnets are pressed accurately and not glued. This allows them to be removed and reused using a pricker.